Technology

Overview

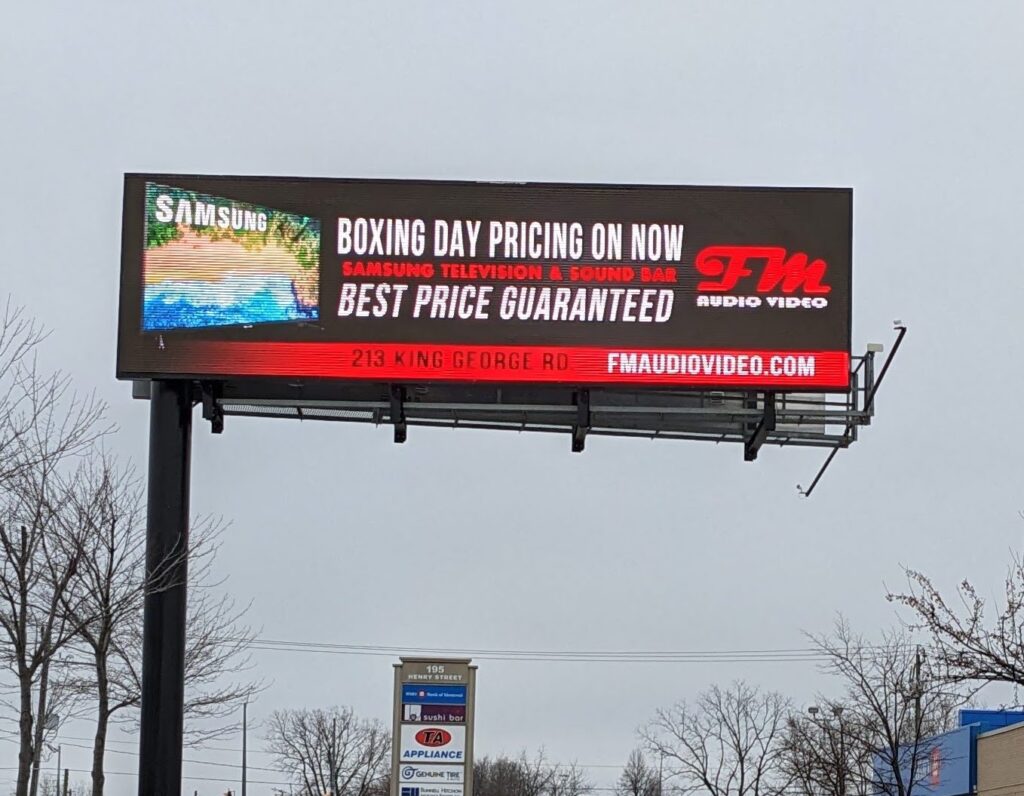

Our products are compliant with safety and electrical standards and codes around the world. The pixels, diodes, boards, ports, cabinets, enclosures, power supplies, wiring, and connectors are all specifically designed and tested for water-tightness and moisture resistance in any type of environment or weather condition. Each component is researched and precisely engineered to withstand rain, snow, high winds and any weather or outdoor temperature variation while offering high-quality performance.

Performance

We continuously monitor our production processes and focus on providing the best quality by paying attention to small details. We take this approach with our supplier network and the extended team as well to always ensure the highest level of workmanship.

Our dedicated manufacturing team and material experts are true leaders in the LED industry. They take great pride in offering a lasting and high-performing product. They work with this mindset, offering world-class and advanced techniques in welding, gluing, soldering, plastic-forming, assembly, LED testing, service, installation, software & IT network management, project management, and more. We build products that last the test of time and we stand behind them.

SMD LEDs stands for Surface Mount Device and Light Emitting Diode. This type of LED module has diodes or pixels mounted directly on one side of the printed circuit board. A single multicolor diode or pixel has three or more individual LEDs within its package, red, green, and blue. These three different colored tiny lights (enclosed together as one), allow many colors or shades of white to be selected, by scaling the brightness of the different colors.

For LED displays that use the alternative DIP technology, each of the LED pixels and light colors is separate from each other. Each red, blue, and green LED diode are clearly visible from up close as separate lights.

Depending on the overall size of the screen, either of these technologies might be right for your project. Smaller higher-end resolution screens with close proximity viewership are typically geared toward SMD products. Larger screens with viewership from further away (like outdoor billboards) are typically geared for DIP products (10mm or higher). That being said, larger-scale projects are getting more and more high resolution as time goes by.

LED screen resolution is measured by the distance from one pixel or Diode to the next (the distance between each pixel) The closer each pixel is to the next, the higher the resolution the display will be.

1-4 mm, pixel to pixel = high resolution

(*Good for viewing the screen from up close and far away)

6-12 mm, pixel to pixel = medium resolution

(*Good for viewing the screen from up close and far away)

16+ mm, pixel to pixel = lower resolution

(*Lower resolution displays still look amazing from far away)